Wire rope lubrication starts with the Viper MK II

Proper lubrication of wire rope will extend operational life and increase safety. Done correctly, it lubricates exterior surfaces as well as the inside wires and core. Proper lubrication will help reduce friction as the individual wires move over each other, and provide corrosion protection.However, lubricating wire ropes can be difficult. Manual lubrication via drip, brush, spatula or rubber glove method is a messy, time-consuming maintenance task and can be hazardous to the environment.

The Viper Wire Rope Lubricator is a much better solution. The Viper Mid MK II provides fast, effective one-pass lubrication of wire ropes from 5/16 in (8 mm) to 2 5/8 in (67 mm) in diameter, at speeds up to 6,670 ft (2,033 m) per hour. It eliminates the slow, labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing LE’s robust wire rope lubricant under high pressure (up to 5,500 psi) right to the core of the wire rope.

LE is the exclusive U.S. distributor for the Viper MK II Wire Rope Lubricator.

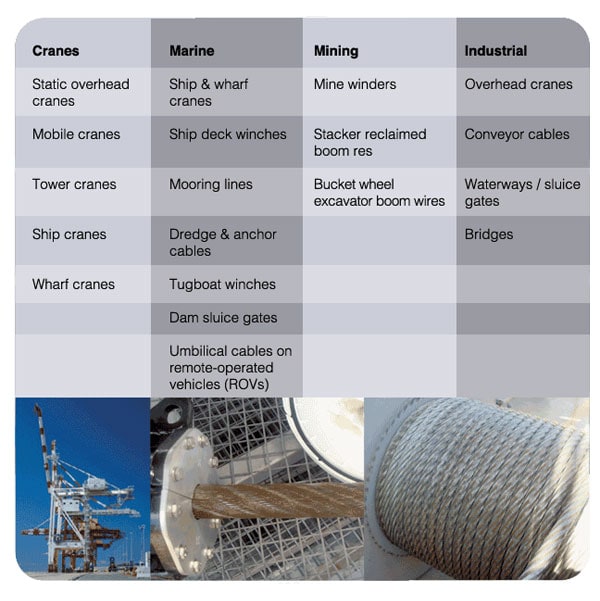

Viper Wire Rope Lubricator is perfectly suited for many uses

The Viper Wire Rope Lubricator can be used in any application where wire rope can be drawn through the collar of the lubricator, including the following typical applications:

Viper benefits far outweigh manual application methods

Single-pass, fast & efficient wire rope lubrication

- Simplifies and speeds up lubricating process

- Lubricates at speeds up to 1.2 miles (2,000 meters) per hour

- Reduces downtime

- Improves equipment availability

Eliminates manual greasing

- Improves safety

- Decreases leakage and mess

- Reduces lubricant usage

High-pressure, high-flow grease pump

- Ensures grease penetration

- Displaces moisture from rope core

- Provides total coverage, even for large ropes

Compatibility with major rope sizes

- Viper Mid MK II lubricates rope sizes 5/16 in (8 mm) to 2-5/8 in (67 mm)

- Viper Maxi MK II lubricates rope sizes up to 165 mm

- Viper Mini MK II lubricates rope sizes 15/64 in (6mm) to 1 13/32 in (36mm)

- Units can be customized

Watch Viper MK II in action in this operational video

How the Viper Wire Rope Lubricator works

The Viper Wire Rope Lubricator consists of a lubricator collar assembly that houses polyurethane seals suited to a specific wire rope size. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar. The steel scraper plates pre-clean the rope by scraping dirt, debris and old lubricant from the rope and protect the seals from loose strands, flattening them out before new lubricant is applied.

As the lubricant is applied with the high-pressure, high-flow grease pump, it forces the lubricant between the strands to the wire rope core. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

Viper system components

The collar is the heart of the Viper MK II. Constructed from high-grade cast aluminum with a robust protective coating, the collar is completed with stainless steel hardware to provide maximum corrosion protection. The MK II collar has built-in handles, making it easy to carry in one hand. One person can easily attach the Viper to the rope.

LE carries the complete standard kit and all necessary components for operation. Configuring the kit is simple. The selection of the seals and scraper plates is based on wire rope size. If you have more than one wire rope size, additional scrapers and seals can be purchased.

The Viper MK II Kit contains:

- Viper MK II high-strength collar

- Viper high-pressure, high-flow grease pump

- Air regulator with gauge & isolation valve

- High-pressure 13-ft (4-m) long, 1/2-in lube delivery hose

- High-pressure lubricant metering valve

- Clear lube drain hose

- Retaining ratchet straps & shackles

- Robust aluminum storage case

- Convenient carry strap for collar

The Viper MK II works best when using our enhanced lubricants

We also carry some of the best wire rope lubricants found in the market to provide you with an entire solution. We recommend that you use Wirelife® Almasol® Coating Grease (452-453) with the Viper Wire Rope Lubricator

Wirelife Almasol Grease is available in NLGI 00 (452-PL, 452-QD, 452-DR) and NGLI 0 (453-PL, 453-QD, 453-DR) grades, both of which are extremely tacky and water resistant and have exceptional penetrating ability. They provide EP protection and exceptional corrosion protection, even in underwater applications

LE offers full-service support for Viper and other lubrication reliability solutions

In addition to wire rope lubrication, LE is happy to offer lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all of our items to help you make the right decision.

To learn more about the Viper Wire Rope Lubricator or about LE’s enhanced lubricants, lubricant training, oil analysis, filtration, lube rooms, breathers, sight glasses or other lubricantreliability solutions, please contact us today.