Right hydraulic oil provides smoother ride for your equipment

It’s no industry secret: One of the best ways to run your hydraulic systems smoothly is to use the right hydraulic fluid. Lubrication Engineers offers a full line of multifunctional hydraulic oils, including several 100 percent synthetic formulations, all of which outperform conventional hydraulic fluids. They provide superior rust prevention, water separation ability, high film strength and excellent handling under extreme pressure. They ensure smooth transition of power and protect metal surfaces from corrosion.

LE hydraulic oils can meet any challenge

Hydraulic systems that operate high-speed, high-pressure hydraulic pumps are common in today’s world. LE’s hydraulic oils are available in a wide range of ISO and SAE grades to meet these and many other critical machinery challenges. Some applications require hydraulic fluids with R & O properties that conform to the vigorous standards of the equipment’s original manufacturers. Other hydraulic applications – such as the bucket trucks that provide electrical service for urban electric grids – require lubricants with low-temperature properties and high dielectric strength for protective insulation. LE’s hydraulic oils offer an array of impressive characteristics to meet these varying standards.

Some of these oils feature high resistance to consistently elevated, turbine-grade temperatures. Others (such as those used for food processing and packaging) need to meet NSF H1 requirements for incidental food contact or meet the USDA H2 criteria for nonfood contact areas of food processing and packaging plants. Still other hydraulic fluids must provide heavy-duty performance in an environmentally friendly formula – in applications such as flood control structures, offshore installations, locks on rivers, dredging equipment and other environmentally sensitive applications. LE’s comprehensive line of hydraulic oils is designed to accommodate diverse lubricant needs.

Look for products that contain Monolec

Monolec®, LE’s in-house wear-reducing additive, creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances, and allowing for opposing surfaces to slide by another. The result is greatly reduced friction, heat and wear. This is of great benefit for mobile and stationary hydraulic systems, such as construction equipment and utility service boom trucks. Learn more about Monolec.

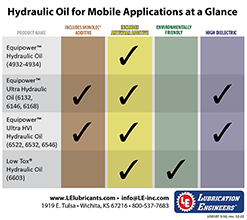

Hydraulic Oil for Mobile & Stationary Applications

Equipower™ Hydraulic Oil (4932-4934)

Anti-wear hydraulic oil designed to assure longer life for bearings and rubbing surfaces. Contains select base oils for oxidation resistance and an additive package that that offers rust protection, anti-wear properties, and thermal stability. Nonfoaming in service and recommended for hydraulic systems operating in highly contaminated environments or where high lubricant consumption is a concern.

Typical Applications: Mobile and stationary hydraulic systems that call for an anti-wear hydraulic fluid

Available ISO Viscosity Grades: 32 (4932), 46 (4933), 68 (4934)

Equipower™ Ultra Hydraulic Oil (6132, 6146, 6168)

A long-lasting, nonfoaming oil designed to protect the life of hydraulic systems, Equipower™ Ultra Hydraulic Oil offers superior protection against water contamination, rust, corrosion and oxidation. This formulation contains Monolec®, LE’s exclusive wear-reducing additive, and is available in three different viscosity grades. It outperforms other commercial hydraulic oils in thermal, oxidative and hydrolytic stability.

Typical Applications: Hydraulic pumps and systems, motors and systems in applications such as: in-plant stations, forklifts, construction equipment, well service equipment and utility service boom trucks

Available ISO Viscosity Grades: 32 (6132), 46 (6146), 68 (6168)

Equipower™ Ultra HVI Hydraulic Oil (6522, 6532, 6546)

A long-lasting, nonfoaming oil designed to extend the life of hydraulic pumps and motors, Equipower Ultra HVI Hydraulic Oil offers superior protection against water contamination, rust, corrosion and oxidation. This high viscosity index formulation contains Monolec, LE’s exclusive wear-reducing additive, and outperforms other commercial hydraulic oils in thermal, oxidative and hydrolytic stability. It is recommended for hydraulic applications with operating temperatures that fluctuate widely on a daily basis.

Typical Applications: Hydraulic pumps, motors and systems found in applications such as construction equipment, well service equipment, utility service boom trucks, forklifts, and in-plant stationary applications.

Available ISO Viscosity Grades: 22 (6522), 32 (6532), 46 (6456)

Hydraulic Oil for Environmentally Sensitive Applications – Low Toxicity & EAL

Low Tox® Hydraulic Oil (6603)

Designed for use where environmental concerns dictate the use of very low-toxicity hydraulic oil, Low Tox Hydraulic Oil is inherently biodegradable and offers superior performance in lubrication, with long oil life and excellent wear protection. There is no worry of premature oxidation or failure of the lubricant as there is with most vegetable oil-based products. Low Tox Hydraulic Oil is formulated with USP quality white mineral oils and specially selected additives to provide a low-toxicity product with good biodegradability that does not sacrifice lubrication performance or necessitate shortening of lubricant change intervals.

Designed for use where environmental concerns dictate the use of very low-toxicity hydraulic oil, Low Tox Hydraulic Oil is inherently biodegradable and offers superior performance in lubrication, with long oil life and excellent wear protection. There is no worry of premature oxidation or failure of the lubricant as there is with most vegetable oil-based products. Low Tox Hydraulic Oil is formulated with USP quality white mineral oils and specially selected additives to provide a low-toxicity product with good biodegradability that does not sacrifice lubrication performance or necessitate shortening of lubricant change intervals.Typical Applications: Flood control structures, off-shore installations, locks on rivers, dredging equipment, forestry/logging equipment, water/wastewater treatment plants, paper mills, mining, and other applications where low toxicity and minimal environmental impact is desirable

Available ISO Viscosity Grades: 68 (6603)

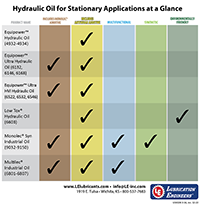

Hydraulic Oil for Stationary Applications

Multilec® Industrial Oil (6801-6807)

Versatile multifunctional Multilec Industrial Oil provides superior long-term anti-wear protection in variety of applications, including stationary hydraulic applications. It is heavy-duty oil designed to prolong equipment life by combating the effects of high temperatures, water, contaminants and heavy loads that accelerate wear. Available in seven different viscosity grades, this multipurpose lubricant is ideally suited for use in all types of air compressors, hydraulics, oil circulating systems, industrial turbines, and R & O industrial and gear applications.

Typical Applications: Air compressors, air line oilers, bearings, blowers, circulating & splash systems, cranes, gearboxes, hydraulics, industrial turbines, vacuum pumps

Available ISO Viscosity Grades: 32 (6801), 46 (6802), 68 (6803), 100 (6804), 150 (6805), 220 (6806), 320 (6807)

Monolec® Syn Industrial Oil (9032-9150 & 9220-9460)

Monolec Syn Industrial Oil is designed to prolong equipment life by combating the effects of high temperatures, contamination and loads that accelerate wear. It is a versatile synthetic lubricant that meets or exceeds the requirements of gearboxes, air compressors, vacuum pumps, hydraulic systems, and roll mill bearings found in the textile, plastic, rubber and paper industries. It is formulated with high-viscosity 100 percent synthetic base oil and a specially developed additive package for applications running at extreme temperatures. The additive package provides outstanding thermal stability and rust and oxidation resistance as well as wear resistance as pressures and temperatures rise. A foam suppressant completes the package. The base oil and additive formulation works synergistically to reduce wear, extend oil drain intervals, reduce oil consumption, and practically eliminate deposits and sludge formation, all while providing excellent compatibility with seals.

Typical Applications: Air compressors (reciprocating & rotary), bearings (oil-lubricated), chains (including dryer chains), gearboxes, hydraulic systems, vacuum pumps, worm Gears (9460 only). Also suitable for use as: circulating oil, AGMA R & O gear oil.

Available ISO Viscosity Grades: 32 (9032), 46 (9046), 68 (9068), 100 (9100), 150 (9150), 220 (9220), 320 (9320), 460 (9460)

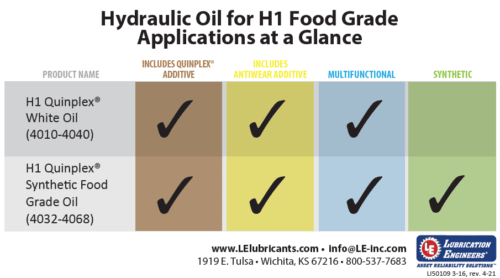

Food Grade Hydraulic Oil

LE manufactures a full line of NSF H1 registered food grade oils and greases for a variety of industrial applications, including the following food grade oils recommended for use in hydraulics. For more information about these and our other LE food grade lubricants, go here.

H1 Quinplex® White Oil (4010-4020)

H1 Quinplex® Synthetic Food Grade Oil (4032-4046)

For more information about LE’s hydraulic oils, please contact us today.