Turbine Oils Formulated for Uptime and Long Life

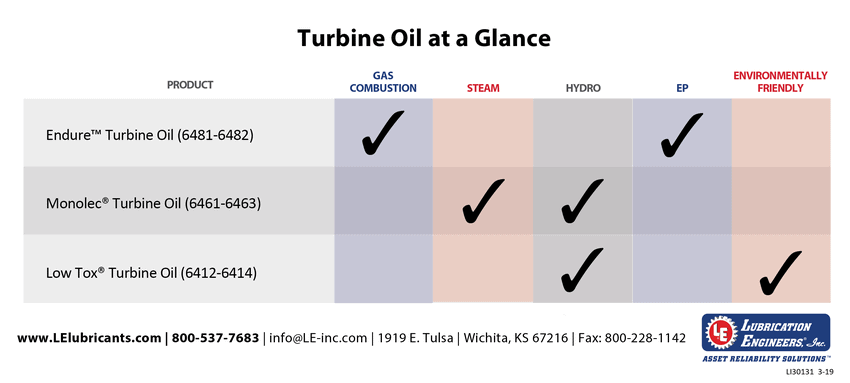

Oil problems are estimated to be the cause of nearly one-fifth of all forced turbine outages, according to “A Comprehensive Guide to Industrial Turbine Lubricants,” by Afton Chemical Corp. Chief among the various mechanisms inside a turbine system that can result in degradation of the oil while in service are oxidation and thermal degradation. Lubrication Engineers has created unique blends of high performing gas combustion turbine oil, combined cycle turbine oil, steam turbine oil, hydroelectric turbine oil and environmentally friendly turbine oil to protect the parts of even the most high-maintenance machines.

Turbine Oil Formulation

Turbine oil formulations are relatively simple; they are a mixture of the following ingredients: Base oil, corrosion inhibitors, oxidation inhibitors, defoamants, and demulsifiers. The base oil is usually 97 percent or more of the turbine oil formula. Additives are blended into the base oil at low levels to protect both the oil and the turbine parts. Additives should be chosen so that they provide optimized performance in the turbine, per OEM requirements. However, many newer turbine oils have been formulated with base oils that were refined with newer techniques. Most laboratory bench test data indicate that the use of these new base fluids should provide longer lubricant life in field applications. Unfortunately, this has not been found to be true. In addition to the newer base fluids, studies have linked certain antioxidant combinations to the formation of sludge and varnish.

Lubrication Engineers has found that its Monolec® Turbine Oils eliminate these problems. How? LE’s Monolec Turbine Oils are formulated using a specially optimized mix of base oils and additives, including Monolec, LE’s exclusive wear-reducing additive. Field experience has shown that this formulation provides the proper synergy between the turbine and the turbine oil. The LE technical staff has conducted hundreds of hours researching, formulating and testing turbine oils to come up with products that exceed performance expectations.

Whether your business relies on mainline turbines or peaking turbines, LE’s premium turbine oils will inject new life into your equipment, relieving it of excessive temperatures and enabling it to bear heavy loads with greater ease. LE’s versatile turbine oils meet or exceed original equipment manufacturer requirements for many turbines, generators and governors; they provide long-lasting performance, excellent water separation, rust and oxidation resistance, nonfoaming performance, and resistance to varnish and sludge formation.

Look for products that contain Monolec

Monolec® is LE’s proprietary liquid wear-reducing additive that creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. An invaluable component in many of LE’s engine oils, industrial oils and other lubricants, Monolec allows opposing metal surfaces to slide by one another, greatly reducing friction, heat and wear. Learn more about Monolec.

Gas Combustion and Combined Cycle Turbine Oil

Endure™ Turbine Oil (6481-6482) is formulated specifically for use in gas combustion turbines, featuring a unique blend of highly refined base oils and proprietary additive technology, including Monolec. Its advanced formula provides superior oxidative and thermal stability while preventing varnish and sludge formation on critical surfaces. Endure Turbine Oil ensures long-lasting, trouble-free performance in gas combustion turbines, minimizing unplanned outages and maximizing uptime.

Turbine Oil Varnish Test

As turbine oil begins to oxidize, byproducts form and start consuming the oil’s antioxidant additives. As oxidation progresses, more and more of these byproducts form and begin to coalesce into larger insoluble bodies. With time, these insoluble bodies plate out as varnish in cooler areas of the turbine system, such as sumps, heat exchangers and hydraulic controls. The varnish can lead to serious situations such as trips or failure to start.

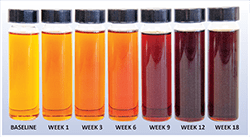

To ensure that its turbine oil would withstand oxidation and avoid these problems for its customers, Lubrication Engineers developed a turbine oil varnish test – TOVT. The purpose of this test is to study the oxidative behavior of new turbine oils in an accelerated oxidative environment, with each week of testing equivalent to approximately one year of real world use in a large-frame combustion turbine, although there are many factors in actual use that could affect oil longevity. TOVT was designed so that samples could be analyzed throughout the test to evaluate the fluid’s condition. Results of this test are as follows.

Endure™ Turbine Oil Withstands Oxidation

Turbine oils can vary widely in color. One of the first indications of oxidation in in-service fluid is color change. As the oils begin to degrade, they experience dramatic color changes and become darker as oxidation byproducts accumulate. To achieve longer lubricant life, competitive turbine oils have been formulated with higher and higher levels of base oil refinement and increasing levels of antioxidants. However, this contributed to varnish and sludge formation in turbine systems. Endure™ Turbine Oil resolves these problems with its unique balanced blend of base oils and additives, specially formulated and proven to inhibit varnish and sludge formation.

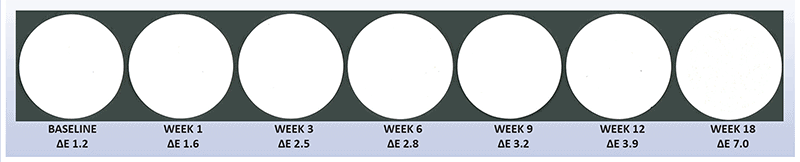

Endure™ Turbine Oil Controls Degradation Byproducts

Most turbine oils have been designed around oxidative stability and longevity; thus, have not been optimized to resist deposit formation. Because of this, formulators have moved toward highly refined base oils, which are oxidatively more stable but have lower solvency power. This results in higher potential for insoluble varnish and sludge formation. LE designed Endure™ Turbine Oil to control the formation of degradation deposits. One of the ways this was accomplished was using a base oil blend that has the solvency power to ensure solubility of any degradation products that form, without sacrificing oxidative stability.

The Membrane Patch Colorimetry test measures the amount of insoluble degradation deposits of in-service turbine oils. After 18 weeks under the same test conditions, Endure’s ΔE values remained normal, indicating the oil contained little to no insoluble deposits.

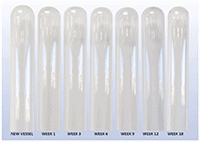

Endure™ Turbine Oil Protects Against Varnish

As increasing levels of oxidative and thermal degradation byproducts, as well as degraded additives, form in the turbine oil, they begin to coalesce into larger molecules, which are insoluble in turbine oil. These insoluble degradation products start to plate out as varnish in the turbine system. The Endure™ Turbine Oil results indicate zero varnish on the vessels after 18 weeks of stress testing.

Some antioxidants used in turbine oils become insoluble byproducts as they are consumed by the oxidation process, then end up contributing to varnish formation. The carefully selected antioxidants in Endure, however, work synergistically to disrupt the oxidation process without causing varnish.

Endure™ Protects Metal Parts

Insoluble degradation byproducts tend to be polar molecules; therefore, they are attracted to metal surfaces, eventually forming varnish on turbine system surfaces. The biggest problem with turbine oils producing varnish is when the varnish affects valve performance in critical control systems. Varnish buildup on control system valves can cause valves to operate sluggishly or stick completely, resulting in costly skipping, failure to start and shutdowns.

Endure™ Turbine Oil protects surfaces in two ways – first, by inhibiting degradation byproducts from polymerizing and becoming insoluble varnish; second, its advanced rust inhibitors and metal deactivators bind to the metal surface and form a protective layer, keeping contaminants away. In addition, Endure’s corrosion control properties prevent wear metals in the oil from causing a harmful chemical reaction, preventing further oil degradation.

Beneficial Qualities

- Exhibits superior oxidative and thermal stability for long-term performance

- Inhibits varnish, sludge and deposit formation

- Exhibits superior air release properties and suppresses foam

- Provides outstanding rust, corrosion and anti-wear protection

- Separates readily from water

- Is filterable for long-term oil cleanliness

Typical Applications: Gas combustion turbines, combined cycle turbines, centrifugal compressors

Available ISO Viscosity Grades: 32 (6481), 46 (6482)

Steam, Combined Cycle and Hydro Turbine Oil

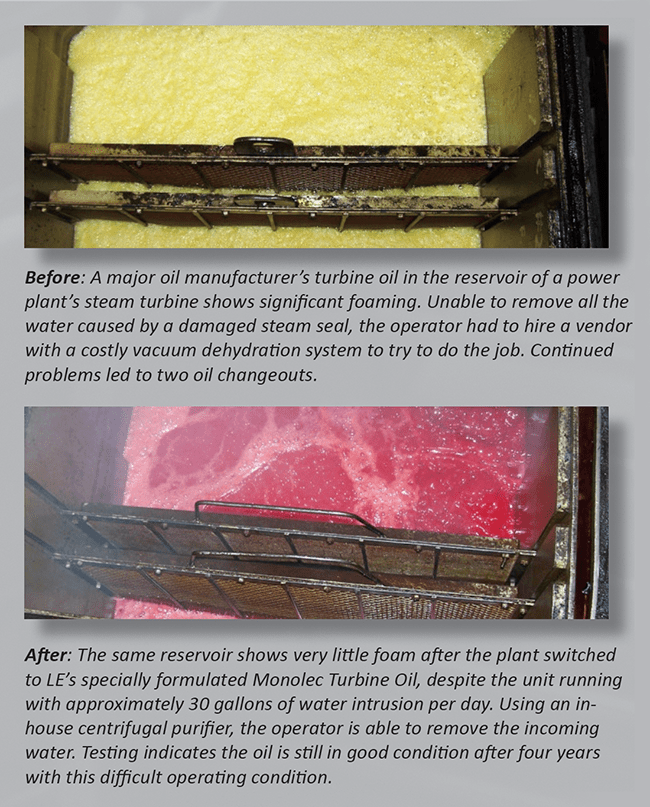

Monolec Turbine Oil (6461-6463) is highly effective for steam, hydro and gas turbine applications. It reduces varnish, reduces water contamination, lengthens equipment life and extends drain intervals. It is a premium, high-performance turbine oil with excellent water separation characteristics, rust and oxidation inhibitors, and improved wear-reducing properties. Its proprietary formula consists of select low-volatility base fluids enhanced with a synergistic mix of high-performance additives.

Beneficial Qualities

- Exhibits excellent thermal stability and provides long-term oxidation resistance and thermal stability

- Resists formation of varnish and sludge

- Reduces water contamination by readily separating from water

- Provides excellent resistance to foaming due to rapid air release properties

- Imparts superior rust protection and maintains a superior film strength

- Protects thrust plates in bearings

- Is easily filtered for long-term oil cleanliness

Typical Applications: Steam turbines, hydro turbines, gas turbine generators, circulating oil systems, centrifugal compressors, other long-service-life applications

Available ISO Viscosity Grades: 32 (6461), 46 (6462), 68 (6463)

Environmentally Friendly Turbine Oil for Hydro Turbine Applications

Low Tox® Turbine Oil (6412-6414) is designed for turbine applications where environmental concerns require the use of a low toxicity oil offering superior performance with long oil life and excellent wear protection, while having the lowest possible effect on the environment. There is no worry of premature oxidation or failure of the lubricant as there is with most vegetable oil-based products. Low Tox Turbine oils are based on USP quality white mineral oils and specially selected additives to provide a low toxicity product with good inherent biodegradability that does not sacrifice lubrication performance or necessitate shortening of lubricant change intervals.

Low Tox Turbine Oil is a low toxicity turbine oil designed with advanced product technology that exceeds the performance of premium turbine oils yet affords low eco-toxicity to address environmental concerns. Has a low order of toxicity compared to standard commercial turbine oils and biodegradable turbine oils. LE’s Low Tox Turbine Oils meet or exceed OEM requirements for many generators, turbines and governors.

Beneficial Qualities

- Reduces eco-toxicity up to tenfold without compromising lubricant performance

- Lasts significantly longer than vegetable-based turbine oils

- Oxidation stability is two to three times better than conventional oils

- Demonstrates excellent demulsibility and seal compatibility

- Resists hydrolysis better than vegetable of synthetic ester based oils

Typical Applications: Hydro turbines, generators, governors, downhole water pumps, forestry and logging equipment, water and wastewater treatment plants, paper mills, elevators

Available ISO Viscosity Grades: 46 (6412), 68 (6413), 100 (6414)

To learn more about our turbine oils and related lubricant reliability products and services, please contact us today.