Lubrication Engineers is a one-stop shop for lubrication reliability.

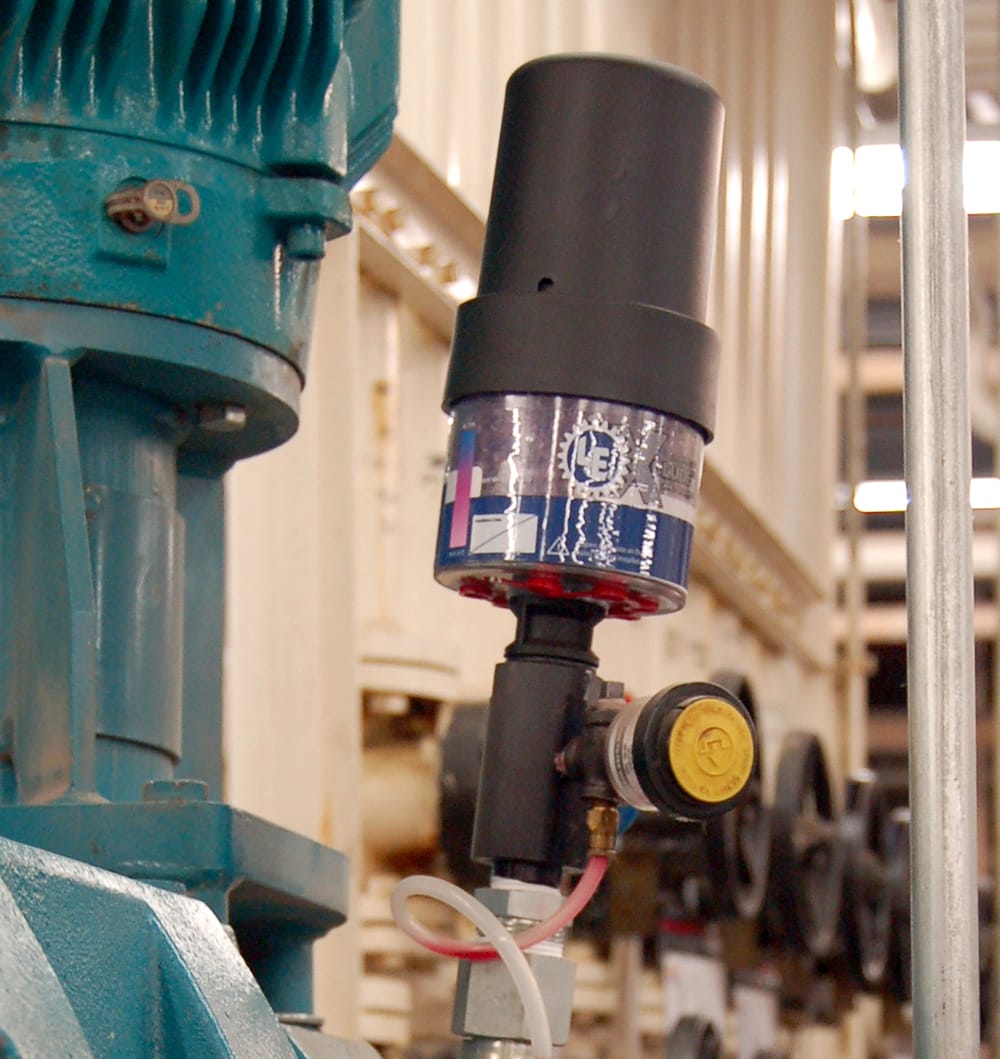

We will work closely with you to learn about your specific equipment and lubrication needs, and then help you create an effective lubrication reliability program that will provide equipment protection and enhanced profits. We start with an onsite equipment assessment. A trained, local lubrication consultant will provide a detailed report recommending lubricants, application methods, usage amounts, and drain or lube intervals. In addition to LE’s premium line of lubricants, your consultant can offer you several other best practice products and services to ensure the effectiveness of your program.