Keep ovens working with superior oven chain lubricants

Process ovens in food processing plants and other manufacturing facilities are vital to production output, but keeping them properly lubricated can be difficult. Extreme temperatures, continuous operation and – in some cases – dirty operating conditions are typical challenges. Offering several high-performance lubricant formulations, Lubrication Engineers has helped companies worldwide with their process oven chain lubrication needs. If you are interested in creating more uptime for your operation, let LE’s experienced and certified consultants help you overcome the challenges of oven chain lubrication.

Proper lubrication reduces wear and saves energy costs

Proper lubrication will keep hot oven chains operating freely and efficiently throughout the process. A good lubricant will penetrate the pins and bushings to prevent corrosion and provide sufficient lubrication. Inferior lubrication, on the other hand, causes many costly side effects. Links and strands may become inflexible, causing rough operation, chains jumping off the sprockets and even breakage. Premature wear to the pins and bushings will shorten chain life, and it causes rapid stretching, a critical failure in machines where equipment or machinery synchronization is a chain function. In addition, increased friction requires more electrical energy for the oven chain to do its work.

LE provides fluid and solid film lubricant options

Oven chains operating at high temperatures can be lubricated in two different ways: with a liquid lubricant or with a solid lubricant suspended in a carrier fluid. Whether liquid or solid, the lubricating film physically separates contacting metal surfaces, thereby reducing friction and wear. LE provides both fluid and solid film lubricants, with recommendations made depending upon the specific needs of your application.

Fluid film lubrication is the regular oil film lubrication used in most ambient temperature applications. This type of lubrication can also be used at higher temperatures, provided you consider the decreased viscosity of the fluid (thinner oil film); the increased oxidation rate of the oil, which causes varnish and sludge; and the volatility of the oil, as it evaporates, there is less oil with which to lubricate.

Solid film lubrication is used at high temperatures or in applications where it is impossible or undesirable to use a liquid. The solid is usually suspended in a liquid carrier designed to disperse (evaporate) after the lubricant has been applied and, in the case of chains, after it has penetrated to the pin area of the chain. Solid lubricants provide a smooth, low-drag surface, which reduces friction, wear, operating temperatures and electrical energy consumption. A successful oven chain lubricant containing solids delivers the solid additives suspended in the lubricant carrier to the pin and bushing areas. As the carrier dissipates, only the necessary lubricating solids are left, coating the metal to prevent wear and corrosion. A good lubricant also will withstand heat over time – resisting oxidation – allowing it to last longer and continue to protect the equipment.

Oven Chain Lubricants Containing no Solids

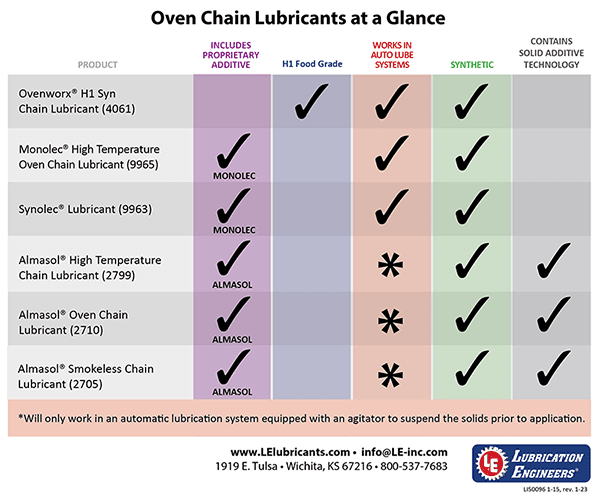

Ovenworx® H1 Syn Chain Lubricant (4061)

Ovenworx® H1 Syn Chain Lubricant (4061) was formulated specifically to combat the demanding conditions present with oven chain applications. It is approved for incidental food contact and contains no artificial dyes, making it a good choice for food manufacturing plants. Oven chain efficiency is dependent upon a lubricant that can keep the chain operating freely and smoothly, fighting the ever-present heat and moisture that can cause corrosion and eventually lead to premature failure of oven chain pins and bushings.

Only the most robust lubricant formulations can perform in this application; it is not an area to cut corners. If the oven chain fails, output comes to a screeching halt. In addition to this high level of protection, equipment runs more cleanly and efficiently with Ovenworx® 4061, which lubricates without the need of solids. Lubricants with solids must be stirred to keep the solids distributed within the carrier and prevent them from falling out of the suspension. Solids also can create housekeeping issues by building up over time, creating gum and gunk around the application area, especially when over-applied.

Typical Applications: Automatic lubrication systems for baking ovens, kiln chain drives, skate chains in bread and bun baking ovens, stenter & tenter chains, other high-temperature oven chains.

Available ISO Viscosity Grades: 220 (4061)

Monolec® High Temperature Oven Chain Lubricant (9965)

Monolec High Temperature Oven Chain Lubricant (9965-9966) is a specially formulated lubricant recommended for use on high-temperature oven chains, providing wear protection and lowering power consumption. It is a USDA H2 lubricant made of a synergistic blend of synthetic base fluids and high-performance additives, including Monolec, LE’s exclusive wear-reducing additive. The synthetic base fluids provide excellent thermal stability and low volatility characteristics at high temperatures, while the additives help the lubricant prevent friction, wear and corrosion.

Typical Applications: Automatic lubrication systems for baking ovens, high-temperature oven chains such as those used in bakery ovens and kilns, kiln chain drives, skate chains in bread and bun baking ovens, stenter & tenter chains.

Available ISO Viscosity Grades: 220 (9965)

Synolec® Lubricant (9963)

Chains and conveyors that operate in high-temperature environments are extremely difficult to lubricate effectively. Synolec Lubricant leaves no deposits to cause chains to bind, jump the sprocket or break, or to cause conveyor rollers to slide or bind. Synolec Lubricant (9963) is a USDA H2 lubricant that can clean off old deposits left by ordinary petroleum lubricants, and its continued use keeps chains, conveyors and bearings operating smoothly. Synolec Lubricant resists rust and oxidation and possesses excellent lubricating qualities to reduce friction and wear.

Typical Applications: Spray or drip lubrication on chains and conveyors under high-temperature conditions. (Do not use where EP lubricant is required.)

Available ISO Viscosity Grades: SAE 40 (9963)

Oven Chain Lubricants Containing Solid Additives

What is Almasol®?

Almasol is LE’s proprietary solid wear-reducing additive that can withstand extremely heavy loads, chemical attack and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear. Read more about Almasol here.

Almasol® High Temperature Chain Lubricant (2799)

Almasol High Temperature Chain Lubricant (2799) is a premium high-temperature USDA H2 chain lubricant that is suitable for application to hot oven chains without interrupting production operations. It contains Almasol, LE’s proprietary wear reducing additive, and other microscopic lubricating solids dispersed in a special high-temperature synthetic carrier. When used as directed, the carrier penetrates to all moving parts, leaving a protective film of lubricating solids as it cleanly volatilizes without residue at high temperatures.

Typical Applications: Hot oven chains; will only work in an automatic lubrication system equipped with agitator to suspend solids prior to application.

Almasol® Oven Chain Lubricant (2710)

Almasol Oven Chain Lubricant (2710) is the solution to trouble-free oven chain lubrication. A USDA H2 lubricant, it contains a synergistic blend of lubricating solids, including submicron-sized Almasol particles, in a specially designed synthetic carrier fluid. The environmentally friendly fluid evaporates, leaving behind a protective film of solids to lubricate chain parts without any accumulation of gum, carbon particles or other hard deposits. The protective solid film is water-resistant and reduces frictional drag over a broad temperature range in excess of the operating temperature of most ovens.

Typical Applications: Oven chains in food processing machinery, such as bakery chains and tortilla oven chains; industrial process oven chains; other chain lubrication applications where solids are required.

Almasol® Smokeless Chain Lubricant (2705)

Almasol Smokeless Chain Lubricant (2705) is a premium grade high-temperature USDA H2 chain lubricant. It is a dispersion of Almasol, LE’s exclusive solid wear-reducing additive, and other submicron lubricating solids in a special high-temperature food grade synthetic carrier. It is suitable for application to hot chains without interrupting production, and will not smoke at temperatures up to approximately 288°C (550°F).

Typical Applications: Bakery and tortilla oven chains and other chain applications where cleanliness is required and a high flash point carrier is needed.

LE offers full-service support for oven chain lubrication

In addition to onsite equipment assessment, consultation and service, LE provides the following customization and value-added options:

- Lubricant conversion

- Automatic lubrication systems

- Lubrication education and training

LE is happy to offer industrial lubricant and reliability recommendations for a variety of oven chain applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our oven chain lubricants as well as our other enhanced lubricants and lubricant reliability products, please contact LE today.