Earthwise product line meets performance & environmental criteria

LE’s Earthwise™ lubricants are specifically formulated to be earth friendly, while still meeting the rigorous demands of industrial applications, including those with significant water exposure. With these products, you can “go green” – and keep up with the latest environmental regulations – without having to sacrifice performance.

What Is an EAL?

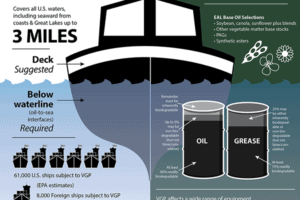

EALs are environmentally acceptable lubricants that are biodegradable and minimally toxic, and are not bioaccumulative – as defined in Appendix A of the 2013 VGP. Each constituent substance in a lubricant formulation must be tested individually to meet the criteria.

EALs & Biodegradability

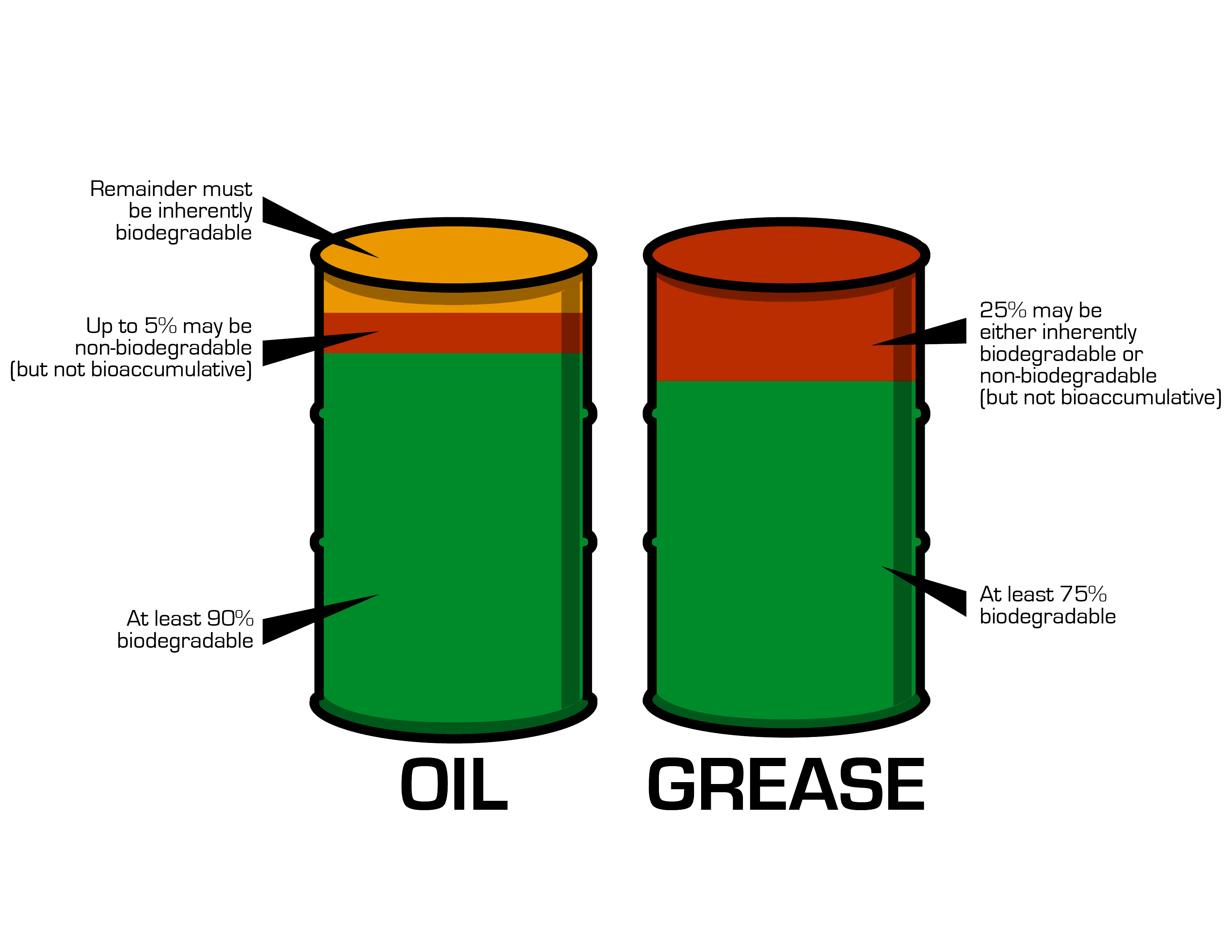

In oil formulations, at least 90 % of the formulation must contain substances that are readily biodegradable. Up to 5% may be non-biodegradable (but not bioaccumulative). The remainder must be inherently biodegradable. In grease formulations, at least 75% of the formulation must contain substances that are readily biodegradable. The remainder may be either inherently biodegradable or non-biodegradable (but not bioaccumulative).

Earthwise™ EAL Wire Rope Grease

Lubrication Engineers has self-certified its first Earthwise™ offering — its EAL Wire Rope Grease — after ensuring that the formulation met all EAL criteria.

Earthwise EAL Wire Rope Grease (3353) is an NLGI 0 grease recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP).

It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation. Its robust additive package, including LE’s proprietary Almasol® and Quinplex® additives, further helps it protect against wear, corrosion, impact, rust and oxidation.

VGP Compliant

- Well-suited for applications in or around waterways

- Formulated with 100% biodegradable base fluid

- Meets VGP standard for aquatic toxicity

- Meets VGP standard for bioaccumulation

- Helps companies be good environmental stewards

Semi-Tacky & Water Resistant

- Clings to metal surfaces, including moving parts

- Stays in place in presence of moisture for long service life

Wear-Reducing

- Reduces wear to wire ropes and all moving parts, including chains and cables

- Protects sprockets, sheaves & other wear-intensive areas

- Seals surfaces, protecting against rust and corrosion

- Shields against acid attack

Smooth-Operating

- Softens shocks

- Enables metal joints and strands to move freely

Available Grade

- NLGI 0

Low Tox® Lubricants

Lubrication Engineers also offers low-toxicity lubricants intended for wire rope, turbines and hydraulics. Although they do not meet the more stringent EAL standards, these products are based on specially selected base oils and additives to provide low toxicity products with good biodegradability that do not sacrifice lubrication performance, require special seals or necessitate shortening lubricant change intervals.

Why low toxicity? One question confronting scientists in environmental risk assessment is whether it is better for a material to be quickly biodegraded and possess relatively high toxicity or be low in toxicity and biodegrade at a slightly slower rate. Lubrication Engineers believes that the latter option provides the best protection of the environment because it minimizes overall impact on the ecosystem.

- Wirelife® Low Tox® Penetrating Lubricant (2011) was designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant. It has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

- Low Tox® Turbine Oil (6412-6414) provides long-lasting performance, equivalent to conventional turbine oils while providing lower toxicity than biodegradable turbine oils. Its advanced technology formulation – with highly refined mineral oil and specially selected additives – offers low toxicity, but it does not sacrifice lubrication performance or necessitate shortening of lubricant change intervals. Low Tox Turbine Oil is especially suited for use in hydroelectric facilities and flood control structures requiring lubricants.

- Low Tox® Hydraulic Oil (6603) provides superior performance – equivalent to premium hydraulic oils – with long oil life and excellent wear protection, while providing lower toxicity than biodegradable hydraulic oils. Its advanced technology formulation – with highly refined mineral oil and specially selected ashless additives – offers low toxicity, but it does not sacrifice lubrication performance or necessitate shortening of lubricant change intervals.

At LE, we are hard at work limiting the environmental impact for industrial customers. Our multifaceted approach can help a company achieve its green sustainability initiatives. For more information about LE’s environmentally acceptable lubricants, please contact us today.