Motor life depends on bearing life, and bearing life depends on proper lubrication.

Are you getting the most out of your electric motors? Many electric motor failures are bearing related, with the bearings never reaching their intended life.

Further, according to the U.S. Department of Energy, more than 70% of electricity consumed in industry comes from the use of electric motors. And, electric motors make up 25% of all rotating equipment in a plant.

Consequently, this means that maximizing your lubrication reliability efforts with electric motors can have a dramatic impact on your uptime and costs. For example, you’ll have less need for repairs and replacements. And, you’ll also use less labor and energy.

With that in mind, we offer lubricants, reliability products, and expertise to help you put together a complete program to maximize the lifespan of your lubricants and electric motor bearings. This in turn will increase safety levels and reduce costs.

Identify Suffering Points

Move forward with LE’s proven solutions for extending equipment life.

Incorrect Grease Selection

Problem

Problem

Use of the wrong grease often leads to early electric motor failures. That’s why selecting the right grease for electric motor applications can make all the difference in the protection and performance of bearings.

LE Solution

LE Solution

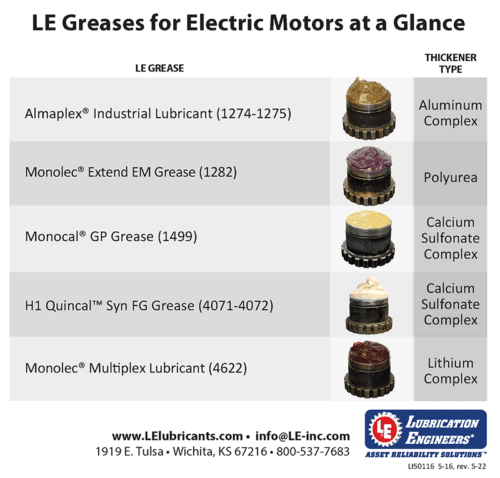

Electric motors require lubricants with specific characteristics. First, the grease consistency preferred for electric motors is normally NLGI 2 or 3, with a base oil viscosity of 100-150 cSt @ 40°C. Second, look for characteristics such as good channeling, low oil bleed, oxidation resistance, anti-wear, and mechanical stability. Third, the preferred thickener for most electric motors is polyurea. However, aluminum complex, lithium complex or calcium sulfonate thickeners are also good options.

Incorrect Grease Application

Problem

Problem

Overgreasing, undergreasing, and not greasing at all are common problems, and all of them can lead to premature electric motor failures. Additionally, operators often must manually grease in hard-to-reach or unsafe areas.

LE Solution

LE Solution

Single-point lubricators decrease motor failures, reduce labor time, and improve safety. Most importantly, your LE consultant can help determine correct lubrication amounts and intervals, then help you choose which single-point lubricator will work best in your application. Our line of SPLs are precision lubrication tools that provide a closed loop system to keep out contaminants. Further, they take the guesswork out of maintenance by supplying the right amount of the right grease at the right time. Finally, they are suitable for indoor and outdoor applications.

Grease Cross-Contamination

Problem

Problem

It is common for a busy operator to pick up a grease gun and apply the wrong grease to the electric motor. As a result of mixing incompatible greases, severe loss of grease performance can occur. This in turn leads to bearing failure.

LE Solution

LE Solution

If manual lubrication is preferred, Clear Grease Guns are the solution for enabling the operator to see the grease before putting it in the application. Further, when combined with a color identification and tagging system, Clear Grease Guns are part of a visual chain of custody for the maintenance operator. Consequently, this simple solution can significantly reduce human error.

Lubrication Reliability Program

In conclusion, Lubrication Engineers can help put together a lubrication reliability program for your electric motors to help them last longer, subsequently eliminating downtime and reducing maintenance costs.

Our certified lubrication experts can be onsite to help put together a program that will bring lubrication excellence to your operation. Get started by finding your local LE consultant or registering to purchase online.